High-Performance Computing Center Stuttgart

For construction engineers working on the project — called Stuttgart 21 — the complex geometry of the columns created unique challenges. Although CAD drawings of the structures existed, the curving volumes and need to precisely arrange an enormous number of steel bars to reinforce the concrete proved more challenging than is the case with more conventional pillars.

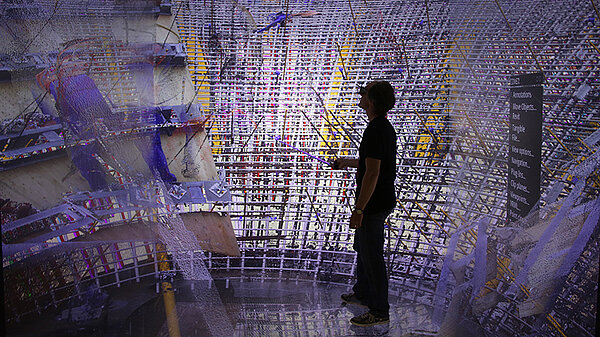

To better plan the structures' fabrication, engineers at the Deutsche Bahn called upon HLRS to develop a 3D visualization. Using CAD and point cloud data, HLRS staff created an interactive digital model of one of the columns for display in the CAVE, a walk-in virtual reality environment.

Meeting at HLRS, representatives of the Deutsche Bahn and construction managers at Ed. Züblin AG could then explore and interact with the visualization to develop a strategy for erecting the column most efficiently and at the highest possible structural integrity. Once the first column was poured onsite, the HLRS team also created 3D scans of the physical structure to compare the virtual model to the actual column and determine whether it had been erected to specifications.

According to Uwe Wössner, who heads the HLRS Visualization Department, "The effort was extremely productive, as the participants had an easier time visualizing the complex geometry, identified problems in the original design, and were able to develop effective solutions. "

—Christopher Williams