High-Performance Computing Center Stuttgart

The Kaplan turbine, developed in 1913 by Viktor Kaplan, was more complex than Francis’ turbine, but offered engineers more flexibility due to its ability to generate power efficiently over a wide range of flow rates. This is especially important in rivers where the intake water pressure can fluctuate, or under circumstances where large vertical drops for water at dams are not possible, such as on rivers with little elevation change.

The Francis and Kaplan turbines, along with the Pelton wheel, represent the overwhelming majority of turbines used in hydroelectric dams today. While these devices can be remarkably resilient—well-maintained Kaplan turbines can be used for more than 50 years in some cases—the demands being put on them in humanity’s changing energy landscape are causing more frequent breakdowns and higher turnover for the turbines. Specifically, as countries scale up other renewable sources of energy such as wind or solar power, the need to more frequently start, stop, and change the flow rate on these turbines is wearing them down.

In an effort to better understand how flow conditions impact turbine reliability, researchers at the University of Stuttgart’s Institute of Fluid Mechanics and Hydraulic Machinery (IHS) have been using supercomputing resources at the High-Performance Computing Center Stuttgart (HLRS) to study these machines at a fundamental level.

“Kaplan turbines have a big operating range, which also means you have to account for different kinds of fluid conditions and what can happen in the turbine,” said Simon Joßberger, a PhD student at the University of Stuttgart and researcher on the project. "The simulation results are normally fine when you simulate at the design operating point, but it is difficult to know if your simulations are right or wrong for a specific turbine when you simulate other operation points, for example at higher and lower flow rates and/or higher and lower hydraulic heads. We need reliable results for Kaplan turbines across the whole operating map, and we need these results during the design process so that we can adapt the turbine to the specific conditions at the operational site."

In order to accurately model the conditions in a turbine using simulations, researchers have to account for the chaotic, turbulent motions of fluid passing through the turbine. When simulating fluid flows on a supercomputer, researchers often divide the area of study into a grid, then calculate the fluid behavior within individual grid boxes for each “time step.” When the size of the grid becomes finer, the interval between time steps is reduced, or the fluid flows faster (or any combination of these factors), the simulation becomes more computationally demanding.

Generally speaking, researchers want to calculate fluid behavior based on fundamental physical principles, with the fewest assumptions possible. However, even the most powerful computers are often incapable of completely calculating fluid behavior across all necessary length and time scales. As a result, certain simulation methods include assumptions about how flows behave at the finest scales.

In perhaps the most fundamental class of turbulence simulations, Reynolds-Averaged Navier-Stokes (RANS) equations, researchers reduce computational complexity by using averages that approximate behavior in turbulent flows. This enables researchers to focus on specific calculations while using reliable assumptions about how other aspects of the fluid might behave.

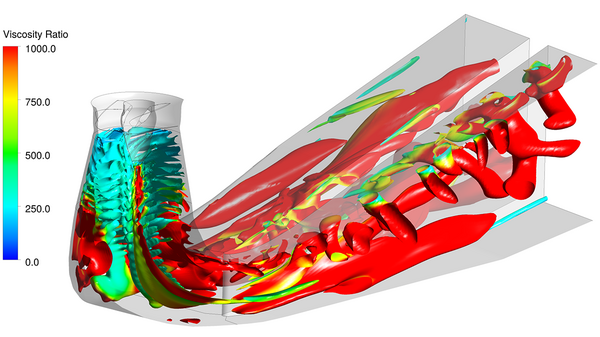

Another class of simulation provides an unvarnished understanding of larger swirling turbulent motions, or eddies, in the fluid. These aptly named large-eddy simulations (LES) enable researchers to focus computational resources on aspects of the fluid that have the largest role in determining turbine efficiency, stress points, or wear and tear during turbine operation.

Using HLRS’s Hawk supercomputer, Joßberger is focused on making the most detailed Kaplan turbine simulation possible by running high-resolution large-eddy simulations whenever possible, supplementing the results with RANS in regions where LES simulation would be computationally too expensive.

Hawk's computing power enables Joßberger to study flow through the turbine at much higher resolution than is usually done. “For what I would call a ‘normal’ unsteady state simulation of a Kaplan turbine, you would normally use 50 to 100 time steps for a single rotation of the turbine,” he said. “Currently, we are running about 1,600 time steps for one rotation. In combination with the much finer computational grid this means that our level of detail is 4 to 5 orders of magnitude greater than what would normally be done.”

In addition to RANS and LES, engineering researchers use supercomputers to do much more complex direct numerical simulations (DNS) that use virtually no assumptions to model fluid behavior. Meaningful DNS that approaches the complexity of real-world conditions or geometries can only be done using the world’s fastest computers, however, and only when focusing on small areas or simple designs. Joßberger sees his work as helping inform and improve modelling and simulation being done at the commercial level.

“The ultimate goal is to understand what is happening in the turbine and then take this information so we can compare it with less complex simulations to see what effects are really important in modelling,” he said. “With this approach, we learn what we need to account for, and what we can actually achieve with smaller or less complex simulations that could be used in industry. The results of this work can serve as a benchmark for assessing the quality of less complex models.”

After having completed simulations for 25 rotations of the turbine, Joßberger feels confident that he can accurately model real-world conditions for the Kaplan turbine under a variety of conditions. Ultimately, his work could help to guarantee that hydroelectric dams remain a reliable, cost-effective source of green energy that support power grids around the world.

-Eric Gedenk

Funding for HLRS's Hawk supercomputer is provided by the Baden-Württemberg Ministry for Science, Research, and the Arts and the German Federal Ministry of Education and Research through the Gauss Centre for Supercomputing.